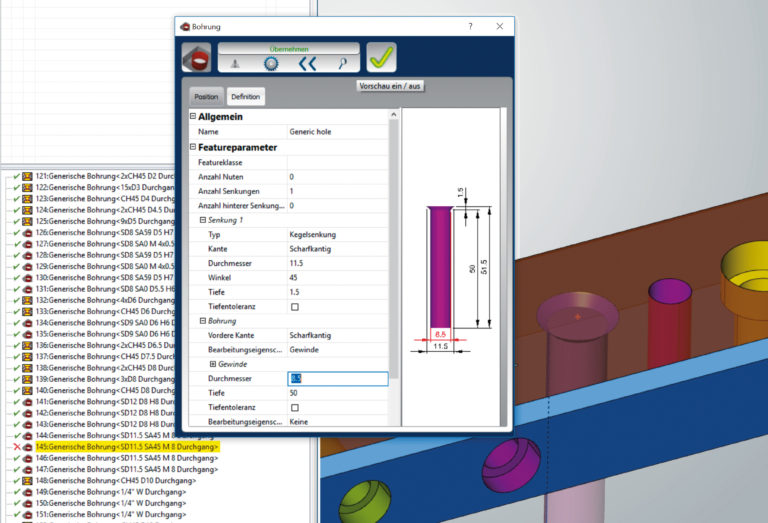

With this functionality, holes can now be programmed within a single feature. The generic hole feature is a new feature type in hyperMILL® intended for 2D and 5axis drilling. Collision checking is available at every stage of programming. Depending on the requirements, this can include a single job, multiple jobs or the entire job list. Integrated machine simulation permits the use of stored machine models to start the simulation directly from within the hyperMILL® job list.

Form creation and adaptation are fully menudriven. With the new report designer, these reports can be created from scratch to suit individual requirements or company guidelines.

HyperMILL® 2011 allows users to predefine job- and tool-list-based reports for the purpose of analysing and documenting machining jobs.

#Hypermill macros full#

64-bit support furthermore provides full use of multi-core processors. Calculations in particular are run with additional stability. This improves performance, especially when creating programs for large parts. HyperMILL®’s 64-bit architecture increases the amount of available memory. OPEN MIND provides consultation and training to assist a customer to define their own CPFs.HyperMILL® 2011 offers new, intelligent solutions that help enterprises with greater efficiency in manufactoring.Ħ4-bit support: For increased performance and process reliability

#Hypermill macros software#

The software thereby enables the creation of a truly complex customer-specific element that can be selected as a single CAM entity and automated on this basis. Once tested and stored, the CPF is recalled and consistently applied with knowledge of the end-user manufacturing processes. With this stored information, complex geometry with a similar structure can be programmed with a few mouse clicks, and with reduced chance of programming errors. The initial steps are to conceive the structure of the CPF, and define the machining steps. Filter schemes within the CPF technology allow for automated selection of geometry, especially when consistent rules (colors, layers, etc) are used in the creation of smart designs. Other parts that share the same geometric structure can be described and machined using the same CPF. The user can select these individual surfaces, assign a name to them (e.g., contact surface), add an image if necessary so that another user also knows what it is, and then combine it all into a CPF. One example is a pocket comprised of a hub surface, a lateral cut-out, an upper edge curve, etc. A curve for example can be a machining contour or a boundary curve, and that manufacturing purpose can also be stored in the CPF. CPFs enable the creation and use of macros. "CPFs allow the linking and naming of any number of geometry selections and associated parameters in one element, and you can also add images and documentation," explains Peter Brambs, head of the Global Engineering Service Group at OPEN MIND. The method is based on process-oriented linking of characteristic geometry sequences with freely defined machining steps. This enables the definition of company standards for CAM programming.Įven complex machining sequences, once defined, can be programmed easily and with automation support using this technology. OPEN MIND Technologies AG has enhanced the 2011 version of its CAM software, hyperMILL, adding an expanded and improved feature technology. Possible applications extend far beyond conventional features.

CPFs allow companies to define individual corporate standards for automated programming. The customised process feature, or CPF, is a special feature technology built into the hyperMILL CAM system.

0 kommentar(er)

0 kommentar(er)